Product Categories

- JQC-06 three - function electronic cleaner

- JQC-08 type electronic yarn cleaner

- QSD-18Z electronic yarn cleaner

- QSD-18 type rotor spinning full function electronic yarn cleaner

- BSQ-1 yarn-doubling length counter

- Untwisted doubling electrical yarn break monitor

- Textile online electronic balance

- Electrical yarn detector

- Sunshine 2000 digital electronic yarn cleaner

Contact us

Shanghai Shanglu Electronics Co. Ltd.

Address: No.5858 humin Road, Shanghai, China

P.C.: 201100

Tel: +86-21-64921304/64989166

Fax: +86-21-64921304

E-mail: 1536503240@qq.com

Url: www.sh-zhengji.cn

Products

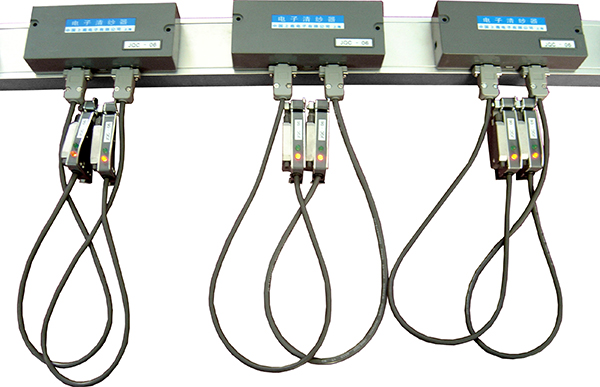

JQC-06 three - function electronic cleaner

.jpg)

This product is the three functions of electronic yarn cleaner according to the characteristics of cocoon silk reeling process and winding process。its principle is to use infrared photoelectric sensor converts the thread diameter into electrical signals. A differential circuit according to the technological requirements of differential thread has defects, when the diameter and length of thread over process settings, the electronic yarn cleaner would send a signal to cutting off the silk,and waits for taking out the defeat by manual work. It has a static function to clearing efficiency bouble silk, ensure the quality of silk.

1. The main features and functions:

1) The rough cleaning principle advanced, has the unique function of static.

2) With electronic detection, does not damage the silk fiber.

3) According to technological requirements set clear brown of the corresponding standards, quantitative removal to defect.

4) Using the principle of infrared photoelectric detection, it is not affected by the environment temperature and humidity.It can effectively overcome the interference of light.

The automatic correction circuit is advanced, can overcome the sensor dust and aging, improve the stability of photoelectric sensor and detection of authenticity.

Each tablet can be interchanged, convenient assembly and disassembly, convenient both machine repair.

Status indication is clear, when no yarn of red light, green light when a yarn for.winding.

2. Main technical parameters:

1) Applicable scope: -20-200denien.

2) Diameter range of short thick place: 0.75-2.75d step adjustment

3) Length range of short thick place: 1-9cm step adjustment

4) Diameter range of long thick place : +0.15-0.55d step adjustment

5) Length range of long thick place: 10-50cm step adjustment

6) Static function setting range and long thick set the range of the same.

7) line speed: 200-1100 M / min.

8) Power supply: -220V/50Hz

9) Error in between the ingot ingot. <5%

10) The scavenging efficiency: >90%

11) The power control box with a load capacity: 60 pounds